Thermoplastic Molding

ADVANTAGES and DISADVANTAGES

In general, thermoplastic injection molding is good for high-volume production runs. If warehousing a high volume of parts is an issue for you, we can provide warehousing with delivery-on-demand from stock. Either way — all at once, or in scheduled JIT deliveries — high volume injection molding will typically give you a lower cost per part.

On the PLUS side...

Lower part costs. The injection molding machines transform the raw resin directly into finished products in one continuous, automated cycle. Everything from refilling the hopper to metering the resin to opening and closing the mold and ejecting parts is fully mechanized by a team of machines. This all means: very low labor costs compared to other molding methods, which translates into lower part costs for you. The one "labor cost" that we don't skimp on is our skilled operators; the high quality and consistency that these injection molding machines offer depends on the knowledge and attention to detail that only well-trained operators can provide.)

On the MINUS side...

Higher mold cost, both in initial expense (thermoplastic injection molds are typically multi-cavity, and have a complex runner / gate system), and in upkeep.

THERMOPLASTIC INJECTION MOLDING:

Prototyping in 2-7 days

Custom Injection Molding with Tonnage ranging from 45-2500 ton

Short Production Lead-time, Inventory Management, Consignment, KanBan, Lean Mfg.

Many high profile companies, representing a wide variety of industries, recognize the value that we offer with this well-coordinated array of services:

Assembly

Gas assist injection molding

Decorating, hot stamp, heat transfer, silk screen, pad print, bar coding

Ultrasonic welding

Integrated component assembly

Product testing

Materials:

We have worked with a broad spectrum of commodity grade and engineering grade resins—ABS, acetal, acrylic, nylons, PP, PE, PVDF, PC, polyesters, TPUs, TPEs, conductive others. Our technical personnel are experienced in processing these materials, and our management has long-standing business relationships with suppliers to offer engineering and material suggestions.

Tooling Capabilities (short tooling lead-times competitive with off-shore pricing):

Electronic Discharge Machining

CNC Machining & Programming

Material Selection Assistance

Mold Design

Engineering Support

Mold Building

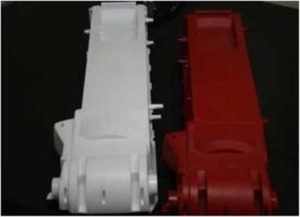

Thermoset Molding

Compression, Transfer and Injection Molding

In many applications, thermoset moldings are economical, feature-rich alternatives to metal castings, even to the extent where some existing metal molds can be converted to thermoset molds, extending the useful life of a design while picking up some superior properties of thermoset materials in the process. For other applications, only thermoset's unique properties, flexible design and economy of production will meet the requirements.

Most of our customers own their own molds, but for reasons of economy and convenience, outsourcing the actual molding and secondary processes makes sense. Our manufacturers’ specialized equipment and trained operators required for high quality thermoset molding are capital-intensive to say the least, and if you can't keep an in-house thermoset line busy, costs can get out of control. Then of course, there's machine maintenance, mold maintenance and storage, resin purchasing and stockpiling, support machinery (preformers and preheaters), secondary operations (deflashing, post-molding inserts, labeling, packaging, palletizing), warehousing, drop-shipping, and scheduling for Just-In-Time (JIT) production delivery. With the capabilities to run lots of jobs at the same time, we keep our lines busy, and your costs down.

Whether you're looking for high-volume production runs, post-production MRO replacement part job shop runs, specialized molding of complex or critical-tolerance pieces, or even design-test prototyping, we can handle the job. And, of course, if you need new tooling — or modifications to existing tooling — we can handle that for you, too.